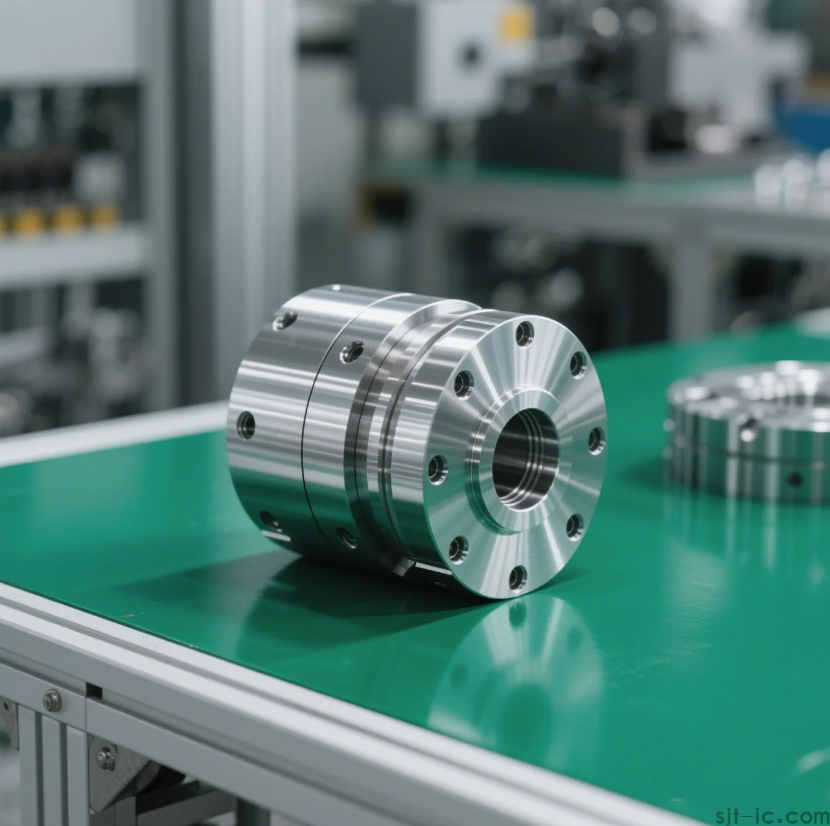

Ever sent out a design for a custom metal part, only to get back something that just... doesn't fit right? 🤔 Maybe the finish is rough, or the dimensions are a hair off. You're not just ordering a part; you're building something that needs to be precise, durable, and perfect for the job. This is where the magic of custom stainless steel CNC Machining comes into play. It's not just about cutting metal; it's about creating a solution tailored specifically to your needs. But how does it actually work, and why is it often the go-to choice for engineers and procurement managers? Let's break it down, step by step.

What is Custom Stainless Steel CNC Machining, Anyway?

Think of it like a super-precise, automated sculptor for metal. You provide a digital blueprint (a 3D model), and the CNC machine follows those instructions to carve a solid block of stainless steel into your exact part. The "custom" part means every single detail—the holes, the curves, the threads—is made specifically for you. It's perfect for when you need a component that you can't just buy off the shelf.

Why Choose Stainless Steel for Your CNC Parts? 🤷♂️

Stainless steel isn't just one thing; it's a family of materials known for being tough cookies. Here’s why people lean towards it:

• It Fights Off Rust: This is the big one. If your part will see moisture, chemicals, or just live outdoors, stainless steel's corrosion resistance is a lifesaver.

• It's Super Strong: These parts can handle a lot of force, pressure, and wear and tear without bending or breaking.

• It Looks the Part: Beyond just working well, it has a clean, professional look that lasts.

However, it's worth mentioning that stainless steel can be a bit tougher to machine than other metals, which might affect the timeline and cost. But for the durability you get, it's often a trade-off worth making.

Okay, But How Do I Actually Get a Quote? 🧐

This is where many people get stuck. It's not like buying a product from a website. You're asking for a custom manufacturing service. To get an accurate price, you'll need to provide a few key things:

1. Your 3D Design File: This is the most important piece. It's the instruction manual for your part.

2. The Specific Stainless Steel Grade: Tell them if you need 304, 316, or another type. This changes the material properties and cost.

3. Quantity Needed: Are you making one prototype or a thousand production parts? Volume makes a big difference.

4. Desired Finish: Do you need a basic mill finish, or something smoother like a brushed or polished look?

Providing clear information upfront is the fastest way to a clear, reliable quote.

A Peek Inside the Process: From Block to Finished Part

I always find it helpful to know what's happening behind the scenes. It builds trust. While every shop is different, the journey of your part might look something like this:

Step 1: Your design file is analyzed and the machine's path is programmed.

Step 2: A solid block of stainless steel is securely clamped into the CNC machine.

Step 3: Cutting tools spin at incredibly high speeds, precisely removing material layer by layer.

Step 4: The part is often finished—deburred, polished, or treated—to meet your specifications.

Step 5: A quality check ensures everything matches your drawing before it's carefully packaged and shipped.

This whole dance is what ensures you get a part that fits and functions exactly as intended.

My Take: Don't Just Shop for Price, Shop for a Partner

Here's a little insight from my experience. The cheapest quote isn't always the best value. A really low price might hint at corners being cut—maybe in material quality, machine calibration, or inspection. What you're really looking for is a manufacturer who communicates clearly, asks good questions about your project, and makes you feel confident that they understand your needs. That partnership is often what makes the difference between a good outcome and a great one.

Getting a custom part made shouldn't be a headache. It should be a solution. If you have a design ready and want to see what it takes to bring it to life, why not get a real conversation started? Reach out to our team today for a personalized consultation and quote. We're here to help. 👍

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque