Feeling overwhelmed by the countless options for a product CNC Machining manufacturer? 🤯 You're not alone. Picking the wrong partner can lead to delayed timelines, poor quality, and wasted budget. But how do you sift through the noise and find a trustworthy partner for your project? Let's break it down together, step by step.

What's the Real Question Behind "How to Choose"?

When people ask "how to choose," they're often secretly asking, "How can I avoid a bad experience?" It's not just about finding someone with a machine; it's about finding a partner who understands your vision, respects your deadlines, and delivers consistent quality. The core of your search shouldn't just be about price, but about reducing risk.

Look Beyond the Price Tag: It's Not Just About Cost

I get it, budget is king. But choosing a manufacturer only based on the lowest quote is a classic mistake. A super low price might suggest they're cutting corners—maybe on material quality or skilled labor.

What to do instead:

- ✅ Ask for a detailed quote breakdown. What exactly are you paying for?

- ✅ Compare a few quotes. If one is drastically lower, see that as a red flag, not a green light.

That being said, everyone has a budget to work with. The goal is to find the best value, not just the lowest number.

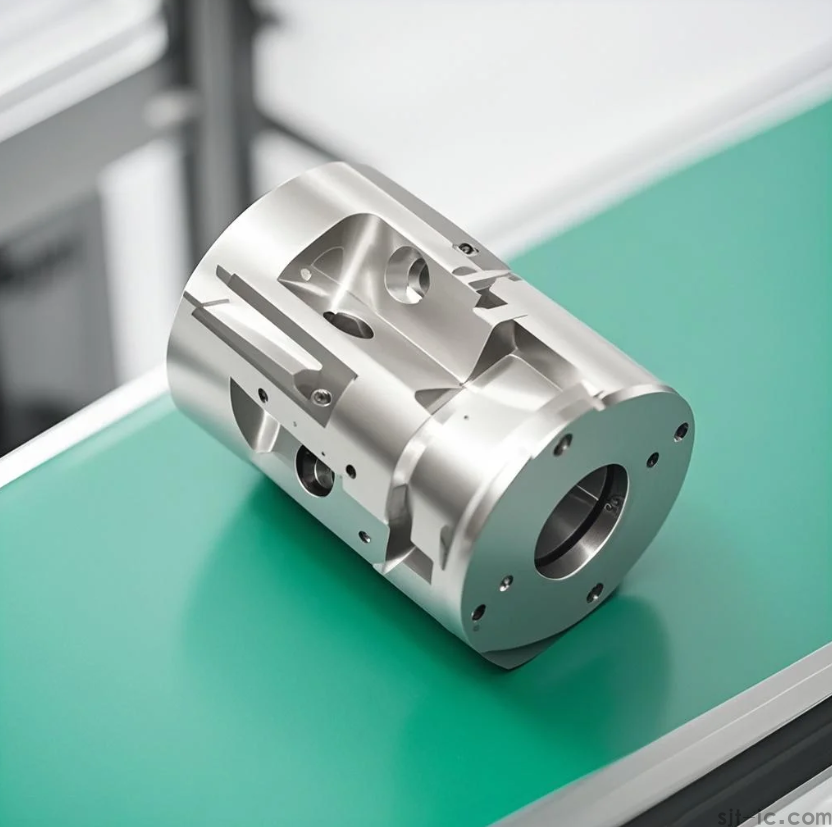

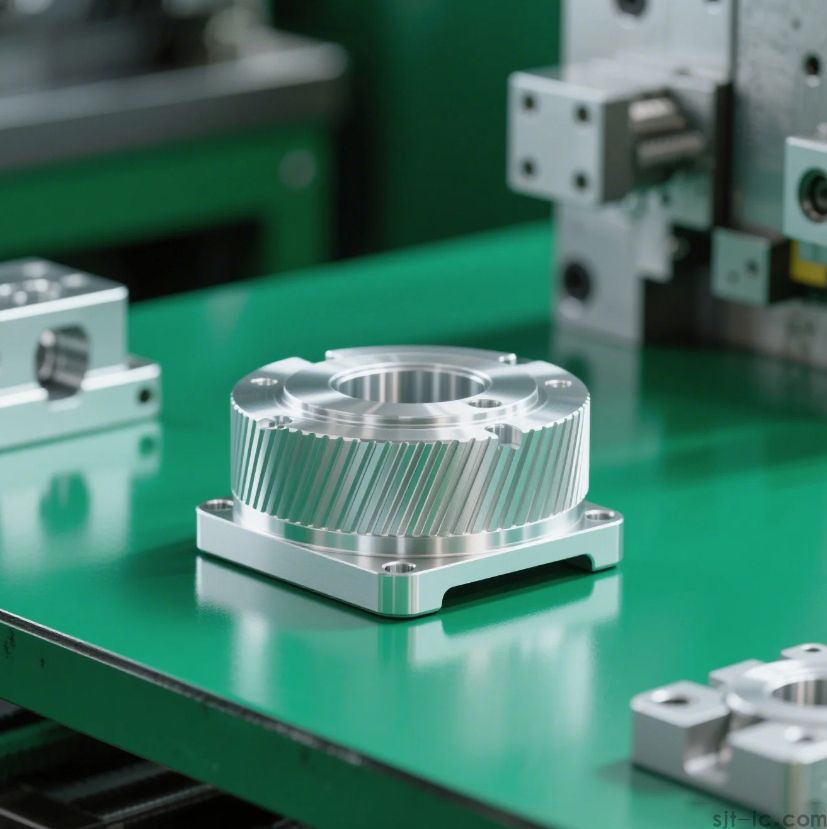

Can They Actually Make YOUR Part? (The Capabilities Check)

Not every shop is equipped for every job. A manufacturer might be great at large aluminum brackets but struggle with tiny, high-precision medical components. You need to check if their machinery and expertise match your part's requirements.

Key questions to ask them:

- 🛠️ What materials do you most often work with? (e.g., aluminum, stainless steel, plastics)

- 🛠️ What is your tolerance range? Can you handle my part's specific precision needs?

- 🛠️ Do you offer secondary services like anodizing or heat treatment?

This step is about ensuring a good technical fit. It saves everyone from a frustrating back-and-forth later on.

The Proof is in the Portfolio (And the Communication)

A manufacturer's past work is their resume. A strong portfolio with diverse projects shows experience. But here's my personal take: a great portfolio with terrible communication is a deal-breaker. 🚩

Pay close attention to how they interact with you from the start. Are they responsive? Do they ask smart questions about your project? This might suggest how they handle problems during production. A partner that communicates well can often save a project from going off track.

So, What's the Next Move?

You've got the framework. Now it's time to take action. Start shortlisting a few manufacturers and put these points to the test. Ask them about their capabilities, request sample reports if possible, and gauge their communication style.

Finding the right product CNC machining partner is a process, but it doesn't have to be a painful one. If you're looking for a service that prioritizes clear communication and has a track record of tackling complex projects, why not start a conversation? Reach out to our team today for a personalized quote and see if we're the right fit for your next project. 😊

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque