Stuck between a massive order minimum and the urgent need for just a few, high-quality elevator components? 🤔 You're not alone. Many procurement managers and engineers face this exact headache: how to get precision CNC parts without committing to warehouse-clogging quantities. This guide cuts right to the chase, showing you how small-batch CNC Machining is the smart solution for prototyping, maintenance, and limited production runs.

What Exactly is Small-Batch CNC Machining for Elevators?

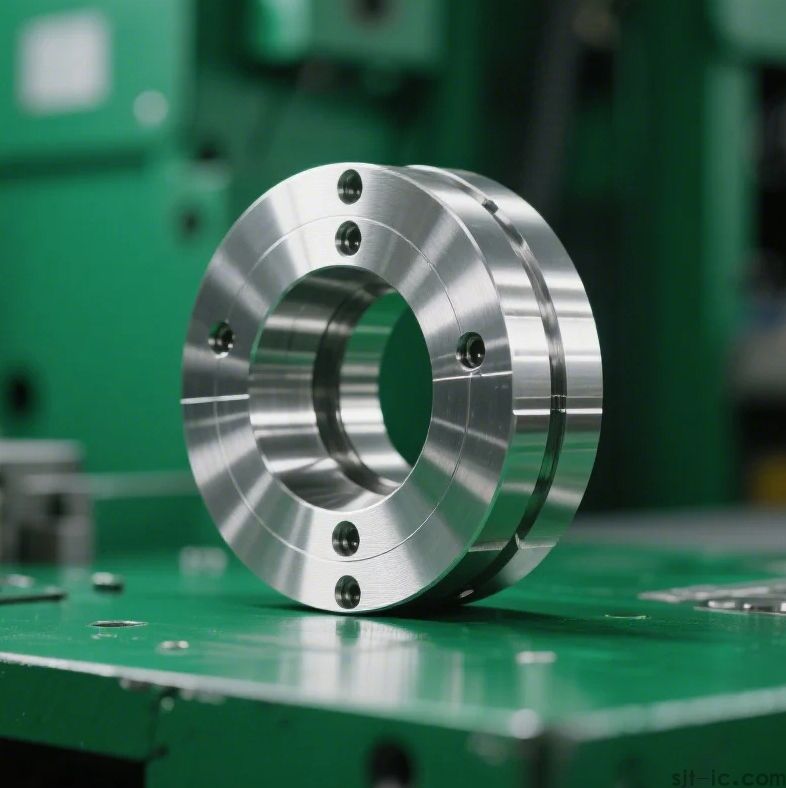

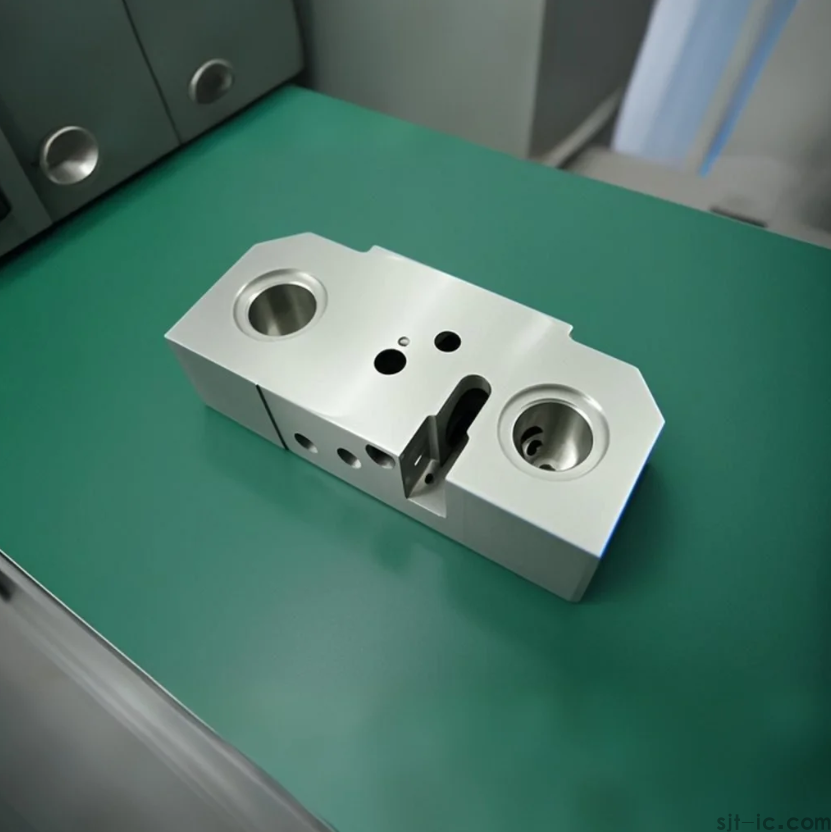

Let's break it down. It's simply using computer-controlled machines to produce limited numbers of elevator components. Think of it as on-demand manufacturing. Instead of ordering 10,000 pieces, you might order 50, 100, or 200. This approach is perfect for specific parts like custom brackets, sensor mounts, or replacement rollers that aren't needed in the thousands all at once.

Why is Small-Batch a Game-Changer for Your Projects?

Big orders have their place, but small batches offer some serious advantages that are hard to ignore.

✅ Lower Upfront Cost & Risk: You're not tying up huge amounts of capital in inventory. This frees up cash flow for other critical areas of your business.

✅ Unbeatable Flexibility: Need to test a design tweak? Small batches let you iterate and improve your components without scrapping a massive, expensive production run.

✅ Faster Turnaround Times: With fewer parts to produce, shops can often get your order done and shipped much quicker, minimizing equipment downtime. ⏱️

That said, the cost per part can be higher than in mass production. But then again, when you factor in storage costs and the risk of obsolete parts, the total cost often balances out, or even tips in your favor.

Key Questions to Ask Before You Order

Jumping in without asking the right questions can lead to trouble. Here’s what you need to know:

What materials work best? While stainless steel and aluminum are super common for their strength and corrosion resistance, the right choice heavily depends on the part's function. Don't just guess; this is where expert advice matters.

How do you ensure quality? Any reputable shop should talk about their quality control process. This might include using precision measuring tools like CMMs or simply having a rigorous final inspection for every single piece.

What about design complexity? CNC machining is fantastic for complex geometries, but extremely intricate internal features might drive up the cost. A good partner will help you design for manufacturability.

Finding the Right Partner: It's More Than Just Price

It's tempting to just pick the cheapest quote. I've been there. But the real value often lies in the service and expertise. You want a partner who gets the elevator industry's standards for safety and reliability.

Look for a shop that asks you questions, offers suggestions, and communicates clearly. A low price means nothing if the parts arrive late, or worse, don't fit. This focus on partnership, perhaps more than anything else, separates the best from the rest.

Ready to Streamline Your Supply Chain?

If managing huge inventories or struggling to find a reliable source for critical spare parts is slowing you down, it's time for a new approach. Small-batch CNC machining offers the agility and precision that modern elevator maintenance and innovation demand.

Have a specific component in mind or want to discuss your project's requirements? Our team specializes in this exact niche. Reach out to our online service team for a personalized consultation and quote today! 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque