Your location:

HOME >

Service >

Numerical control machining > CNC Machining Strong Flashlight Housing

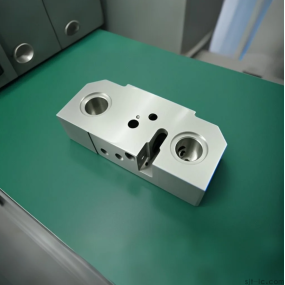

CNC Machining Strong Flashlight Housing

As a leading CNC machining service provider, EMAR specializes in manufacturing precision components like flashlight housings for industrial and commercial applications. This articl

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision components like flashlight housings for industrial and commercial applications. This article explores the technical process and advantages of CNC machining strong flashlight housings.

Why Choose CNC Machining for Flashlight Housings?

Flashlight housings require exceptional durability, heat dissipation, and dimensional accuracy. CNC machining offers:

- ±.01mm precision for perfect component fit

- Superior surface finish (Ra .8μm achievable)

- Material versatility (aluminum, titanium, or engineering plastics)

- Integrated threading and heat sink features

Our Manufacturing Process

EMAR's 5-axis CNC centers execute a rigorous production workflow:

- Material certification (Aerospace-grade aluminum verification)

- Pre-machining stress relief

- Precision milling with carbide tools

- Deburring and surface treatment

- 3D measurement inspection (CMM verified)

Technical Advantages at EMAR

Our facility features:

- 15+ HAAS CNC machines with thermal compensation

- In-house tooling workshop for custom solutions

- IP54-rated clean room for critical components

- Material traceability system

For flashlight manufacturers requiring military-grade or IP68-rated housings, our team provides DFM analysis and prototyping within 72 hours. Contact our engineering team at www.sjt-ic.com for technical specifications and batch production quotes.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque